IBM Selectric

History and Basic Info

The IBM Selectric typewriter was introduced on the 31st of July, 1961. This typewriter is equipped with a golfball sized type element instead of a type basket so that typefaces can be easily interchanged. The series started with the IBM Selectric (It's original designation does not include a I, but for consistency's sake, people usually call it the "IBM Selectric I" or just "Selectric I") , which evolved into the IBM Selectric II, and finally the IBM Selectric III. Selectrics came in a few sizes; (from smallest to largest) the Personal, 12",13" and 15".

The Typeball

The IBM Selectric's typeball gives it some major advantages over a traditional typewriter. Typeballs can be swapped out quickly allowing for multiple typefaces on one machine, the selecting mechanism is much faster than a traditional typewriter, and some machines are even equipped with IBM's "Dual Pitch" option which allows the machine to type in both 10 cpi (Pica) and 12 cpi (elite).

The typeballs for all Selectrics are not all interchangeable. The Selectric I and II require typeballs that are labeled in white. The Selectric III can only use typeballs labeled in yellow. The difference between these typeballs is the number of characters available on the typeball itself.

Common Issues

Due to their reliance on lubrication and complexity, IBM Selectrics will often not work when you first get your hands on it. Some times they won't even turn on. There are (usually) about 3 different issues that are universal to every machine.

- The first major issue is grease and oil. Selectric repairmen often greased and oiled every little nook and cranny on these machines to keep them running smoothly. Unfortunately, after sitting for 30-40 years, this grease will dry out, harden, and/or become extremely gummy. This, as you can imagine, is not good for the machine. You will want to bring it into a shop to have it done professionally, or if you are feeling adventurous, you can do it yourself with the help from some repair and adjustment manuals and some youtube videos.

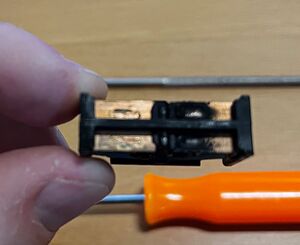

- The second major issues is the central drive hub. These were made out of plastic hubs with metal cores. Usually there is nothing wrong with the metal core. The issue is the plastic hub. These are somewhat fragile, and after many years of use and/or sitting, they crack. A cracked hub will only hold together for so long and will eventually crack fatally. Duane from Pheonix Typewriter has a very good repair to this issue, linked here

- The third major issue is the drive belt. These will often shed teeth after sitting and disintegrating for many years on startup. Sometimes these belts are ok, but often they need replacing.

- Another common issue has to do with the torque limiter extension spring getting stretched and needing replacement. If your carrier doesn't return after pressing the "return" button, this is the likely cause. The spring is a part of the return clutch assembly and torque limiter, located on the operational shaft, beneath the right dust cover. The part can be ordered off of eBay and the assembly can be cleaned and lubricated, and the spring easily replaced, with assistance of this video: linked here. NOTE: cleaning/spring replacement can be accomplished without moving the shaft as in the video.

- If your Selectric is making a light chirping noise it is likely the motor pulley bushing. These are small plastic pieces that wear out, disintegrate or simply fall out over time. They can be ordered off of eBay and replaced as shown in this video: here.

- If your Selectric (any generation) is slow to power on, or doesn't power on at all, there is a strong possibility that the internal power switch simply needs to be taken apart and cleaned. Duane from Phoenix Typewriter has a video explaining how to do this here.